How Carbon Fiber Mirrors Are Snagging the Future of Astronomy

Scientists cook up superlight carbon fiber mirrors for telescopes. Forget heavy glass, these resin-baked wonders are ready in days, not weeks, and promise clearer views of the cosmos from space and backyard alike.

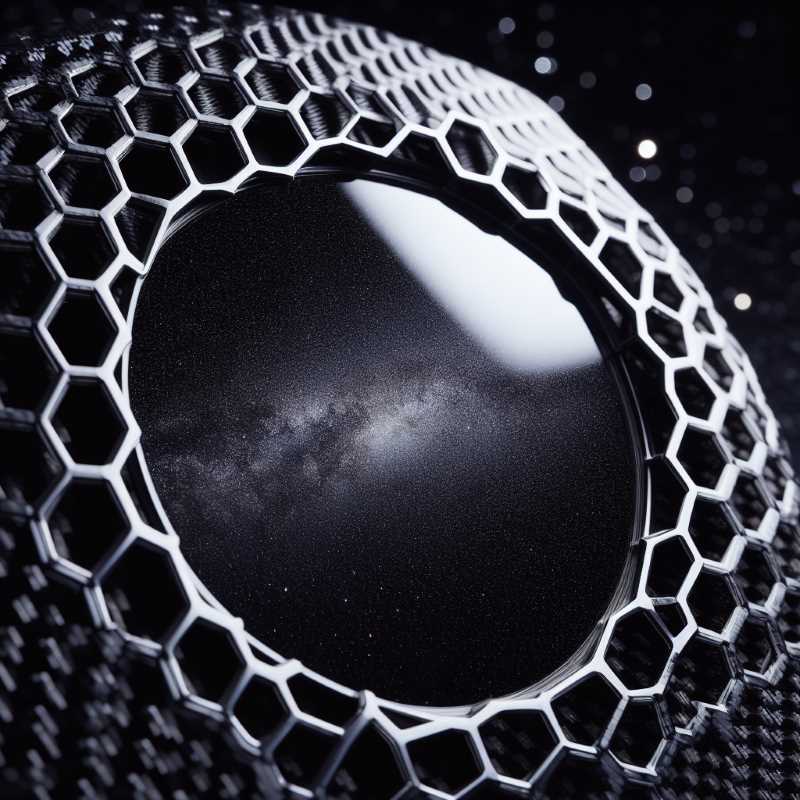

Forget the apples and step aside, Snow White. In the realm of science, a new kind of mirror is taking center stage, and it's made not of glass, but of the stuff that dreams and tennis rackets are made of: carbon fiber. Researchers at the Institute of Astronomy (IA) of UNAM in Mexico have whipped up a recipe for superlight, high-quality carbon fiber mirrors that could change the game for astronomical observations and telescope tech in general.

Imagine a telescope that sheds the pounds but keeps the punch. That's the promise of these carbon fiber marvels. Traditional glass mirrors, like the ones peering into the cosmos from the mighty James Webb, are hefty beasts. Polishing them to perfection is a time-consuming, skill-intensive process that can take weeks. But these new carbon fiber creations are like sleek gazelles, ready to waltz across the celestial stage in a mere three to five days.

So, how do they cook up these cosmic gems? The key ingredient is a technique called “mirror replication.” It's like baking a cake, but instead of batter, you're pouring resin over a 3D-printed mold with a honeycomb-like structure. This honeycomb acts as a built-in lattice, eliminating the need for that tedious polishing step. It's like skipping straight to the frosting – and it's just as delicious (for astronomers, at least).

The result? Mirrors that are not only feather-light but also deliver stunningly crisp views of the cosmos. And the best part? This recipe is scalable. While the current batch is limited to 20-centimeter mirrors, the future holds possibilities for baking up six-meter behemoths that could grace professional telescopes.

Think of the possibilities! These carbon fiber mirrors could be the secret sauce for next-generation astronomical instruments. They could equip nimble robotic telescopes, embark on extraterrestrial adventures, and even make backyard stargazing a breeze (no more lugging around a telescope that weighs more than your cat).

So, the next time you gaze up at the stars, remember – a revolution in telescope tech might just be brewing in a lab, and it's all thanks to a team of scientists with a passion for lightweight, high-quality mirrors. And who knows, maybe one day, we'll all be able to enjoy a slice of the astronomical pie, thanks to this revolutionary recipe.

Key Ingredients:

- Carbon fiber – the magic dust that makes these mirrors light as a feather.

- 3D-printed molds – the honeycomb base that gives the mirrors their perfect shape.

- Resin – the glue that holds it all together.

- A sprinkle of innovation and a dash of scientific genius.

Instructions:

- Preheat the 3D printer to honeycomb-building temperature.

- Whip up a batch of resin, ensuring it's smooth and free of lumps.

- Gently pour the resin over the mold, letting it fill every nook and cranny.

- Bake for a few days, allowing the resin to cure and harden.

- Voilà! Your carbon fiber mirror is ready to take on the universe.

Remember: This recipe is still under development, so it's best to leave the baking to the professionals for now. But keep an eye on the horizon – these carbon fiber mirrors might just be the future of astronomical observations.

Bonus Tip: For an extra cosmic kick, serve your carbon fiber mirror with a side of dark matter and a sprinkle of stardust.