Mexican Scientists Find Value in Shrimp Shells for Medical and Industrial Uses

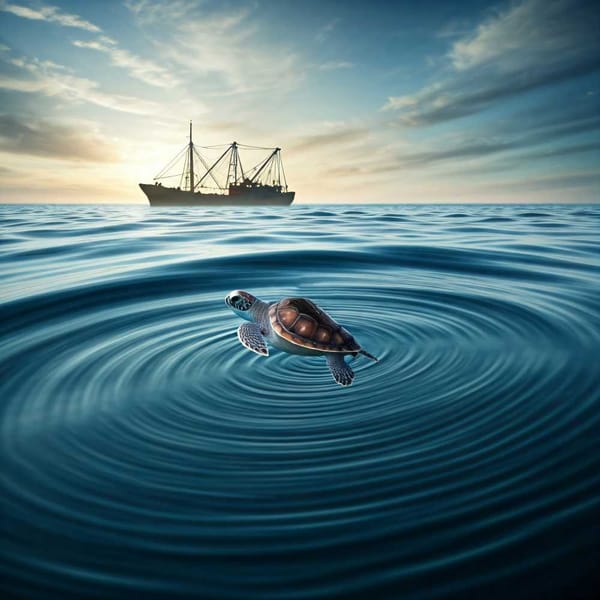

Mexican researchers use lactic acid bacteria to extract chitosan, a valuable biopolymer, from shrimp shell waste. This eco-friendly method transforms a pollutant into a resource for medicine, agriculture, and even 3D-printed tissues.

A team of academics in Mexico is turning what was once considered seafood waste into a potentially valuable resource for medicine, agriculture, and other industries. Researchers from the Faculty of Higher Studies (FES) Cuautitlán of the National Autonomous University of Mexico (UNAM) and the Technological Institute of Higher Studies of Ecatepec (TESE) have developed a biotechnological process to extract chitosan, a versatile biopolymer, from discarded shrimp shells.

This innovative approach addresses two key issues: the environmental impact of seafood processing waste and the growing demand for sustainable materials in various sectors. Mexico is a major player in the global shrimp market, ranking second in Latin America and eighth worldwide in production, according to the researchers. This robust industry, however, generates substantial waste, with approximately 45% of processed shrimp ending up as refuse.

“This waste represents a potential contaminant,” says Martín R. Cruz Díaz, one of the researchers from FES Cuautitlán. By utilizing this byproduct, the research team aims to “provide high added value” while exploring new applications for chitosan.

The process involves a “green extraction” method using lactic bacteria, commonly found in dairy products and probiotic supplements. The research team, including Ana María Sixto Berrocal, Susana Patricia Miranda Castro (both from FES Cuautitlán), and María Aurora Martínez Trujillo (from TESE), employs a two-stage process within a bioreactor.

First, the shrimp shells, after being dried, washed, and sifted, are subjected to the action of two types of lactic bacteria: Bifidobacterium lactis and Lactobacillus delbrueckii. The Bifidobacterium lactis produces proteases, enzymes that break down proteins attached to the shells. Subsequently, Lactobacillus delbrueckii generates lactic acid, which removes calcium. This process yields chitin, a structural component of crustacean shells, similar to cellulose in plants.

The second stage involves deacetylation, a chemical process that transforms chitin into chitosan. This resulting substance is water-soluble and possesses a range of desirable properties.

Chitosan’s versatility is a key driver of this research. The researchers highlight its potential applications across multiple sectors. In agriculture, it can be used in fertilizers. In the pharmaceutical, food, and cosmetic industries, it finds applications in various products. Notably, in the health sector, chitosan is being explored for drug delivery, wound dressings for burns and injuries, and even surgical sutures due to its biocompatibility and ability to promote cell regeneration.

“Chitosan is a soluble polymer with multiple applications,” explains Mr. Cruz Díaz. He further elaborated on its use in formulating gels for cell therapy and creating scaffolds for cell cultures. The researchers are particularly interested in using 3D printing technology to create these scaffolds, serving as a support structure for cells to grow and potentially develop artificial tissues and even organs in a laboratory setting. This ambition to “cultivate organs at the laboratory level with chitosan” represents a significant potential breakthrough in regenerative medicine.

The research not only offers a solution for managing seafood waste but also presents a compelling case for the economic potential of biopolymers. By transforming a waste product into a valuable material with diverse applications, the Mexican research team is demonstrating the power of biotechnology to create sustainable and economically viable solutions. The project, still in its developmental stages, has the potential to create new markets and contribute to the growth of various industries, from agriculture to advanced medical therapies.